Oil/Water Separation:

Demulsifier

Achieve Cleaner Oil. Faster Separation. Field-Proven Results.

In crude oil production, water-in-oil emulsions are more than a nuisance; they impact oil quality, downstream processing, and regulatory compliance. Rodanco’s advanced DM series demulsifiers are engineered not just to separate water efficiently, but to improve the overall quality of your produced oil by reducing salts, solids, and ensuring on-spec delivery.

More Than Just Separation: It's Precision Chemistry

Rodanco’s demulsifiers go beyond the industry standard. We understand that every oil field is different, and off-the-shelf solutions don’t always deliver consistent results. That’s why our demulsifier program is built around customization, speed, and scientific validation.

We offer:

- A Comprehensive Demulsifier Kit

25 preformulated products

35+ ready-to-blend intermediates

Carefully selected by our R&D chemists to match a wide range of emulsion characteristics and crude profiles.

- On-Site Bottle Testing Expertise

Our field team includes experienced bottle testers who conduct real-time evaluations under your site’s actual conditions. With proven methodology and decades of combined experience, we ensure rapid formulation adjustments for peak performance.

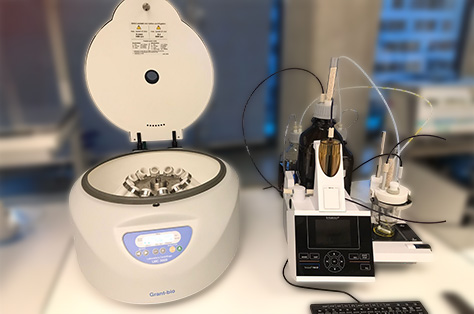

- Complete Test Equipment: Always Ready

Rodanco maintains fully equipped bottle testing kits; including water baths, centrifuges, calibrated pipettes, and more readily available at key logistical hubs like Libya or deployable globally within short lead times.

Field Testing Excellence

Tailored Solutions for Complex Emulsions

From sweet to heavy crudes, from conventional to challenging offshore fields, our DM demulsifier series includes field-validated solutions that have delivered results across geographies. But we don’t stop there. Based on bottle test results and site-specific conditions, we develop tailor-made demulsifier blends that adapt to:

- Changing reservoir chemistries

- Seasonal operational variables

- Regulatory water content thresholds

- Salt and sediment control requirements

Why Choose Rodanco?

Global Reach with Local Speed

Whether in North Africa, the Middle East, or Southeast Asia, our kits and experts are positioned to respond fast.

Lab Backed, Field Tested

We bridge the lab-to-field gap with formulations validated both in test tubes and in real wells.

Iterative Optimization

We don't stop after one test. We keep refining until you get consistent separation, minimal residual water, and reduced BS&W.

Tech-Driven Customization

We match molecular properties with emulsion behavior using our ready-to-blend inventory, minimizing trial cycles and maximizing uptime.

Results You Can See

BEFORE

Persistent water-in-oil emulsion causing quality issues and processing delays

AFTER

Clean separation with reduced water content and improved oil quality specifications

Get the Most from Every Barrel

Your oil deserves better than generic chemistry. With Rodanco’s demulsifiers, you’ll reduce

reprocessing, avoid corrosion, and maintain contractual oil specs every time.

Download our Rodanco Company Brochure

Rodanco Company Brochure

Discover Our Other Solutions

- Oil Field Chemicals

Production Optimization:

• Oil/Water Separation: Demulsifiers

• Naphthenate Management

• Deoilers/Water Clarifiers

• Foam Management

• Gas Production Drying Agent

Flow Assurance:

• Wax Management

• Asphaltene Management

• Scale Management

• Hydrate Management

Asset Integrity:

• Corrosion Inhibitors

• Bacteria Management

• H2S Scavengers

• Oxygen Scavengers

- Finished Fuel Additives

• Metal Deactivators

• Fuels Flow Assurance Additives

• Cold Flow Improvers (CFIs)

• Wax Dispersants (WASA)

• Filter Blocking Tendency Improver

• Pour Point Depressant for Marine Fuels

• Asphaltene Inhibitors

• Octane Number Improvers

• Cetane Number Improvers

• Lubricity Improvers

• Conductivity Improvers

• Fuel Corrosion Inhibitors

• Dehazers

• Fuel Dyes and Markers

- Industrial Cleaners

• General Purpose Industrial Cleaners

• Solvent Based Heavy-Duty Cleaners (Tank Cleaners)

• Biomass Cleaners

• Polymer Cleaners

• Descalers

- Slop Oil Breakers

Specialized solutions for breaking slop oil emulsions and recovering valuable oil resources

- Water Treatment

• Bioflocculants

Advanced water treatment solutions for industrial applications

Contact Us

Follow Us on LinkedIn

Ready to Optimize Your Oil Quality?

that delivers consistent, field-proven results for your specific crude

profile.